Technology

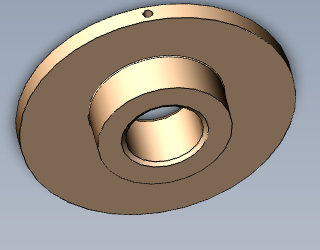

Pacific Gear Systems, Inc. utilizes Solid Works 3D Cad Modeling to develop our designs for the ease of manufacturing.

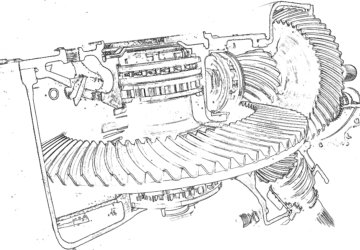

By using 3D modeling we can produce models that aids in rapid proto-typing design capabilities to actually producing 3D stereo-lithograph models to check and verify our type design features. Stereolithography (SLA) is one of the easiest and quickest ways to prototype a physical model of our parts to verify form, fit, and function as well as design verification of splined and gear teeth features of many parts. An SLA prototype saves time and money by avoiding costly mistakes before going to production.

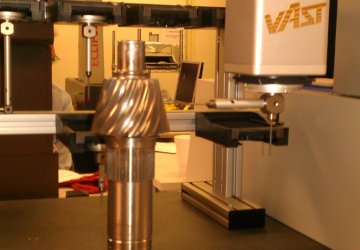

3D modeling also aids in faster planning and program writing for CNC Machining equipment. Our models also allow us to verify features that can be checked from optical inspection devises.